Function summary:

SHT4605 microcomputer controlled electro-hydraulic servo universal testing machine adopts double space cylinder lower structure。There is a compression space between the test bench and the lower beam, which can realize the compression, bending, shearing test of the sample.The tensile space is between the lower beam and the upper beam, and the tensile test of the sample is mainly carried out。The test space is automatically adjusted by rotating the lead screw to move the lower beam up and down。The closed-loop servo control system composed of electrical controller, servo valve, load sensor, displacement sensor, extensometer and computer can control the test process automatically and accurately, and measure test parameters such as test force, displacement and deformation automatically。

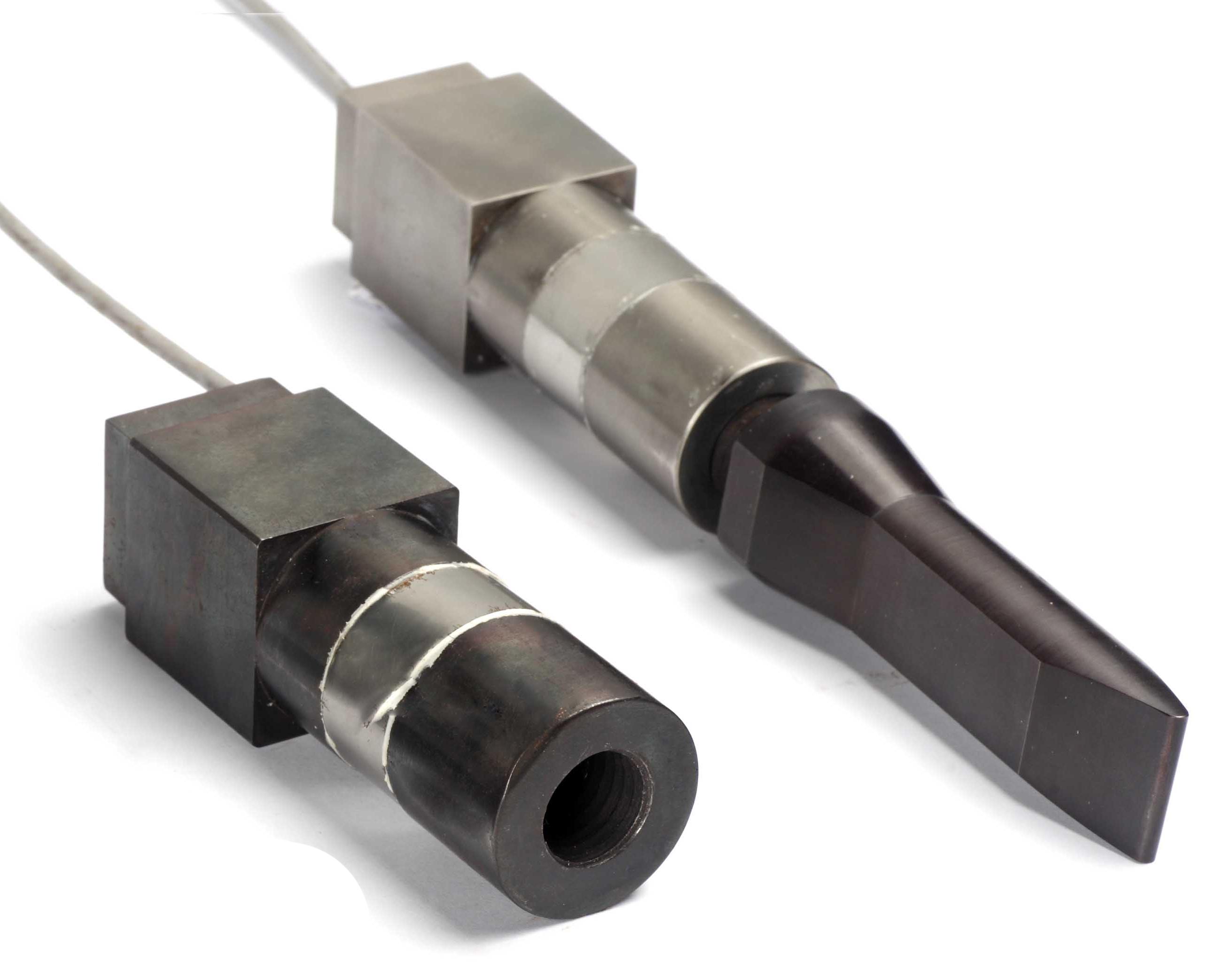

The testing machine is mainly used for tensile, compression, bending, shearing and other tests of metal materials.It can realize the test of equal rate loading, equal rate deformation and equal rate displacement, and can realize the control of force, deformation and displacement in one test, and the control can be smoothly switched between。The software can automatically calculate ReH (upper yield strength), ReL(lower yield strength), Rp0.2(specified non-proportional elongation strength), Rt0.5(specify the total extension strength), Rm(tensile strength), E(elastic modulus) and other parameters。

The user can also configure the fixture to complete the tests specified in other standards。

The computer and the measurement and control system collect the test data and send the control instructions, which can automatically control the test process and automatically calculate the test results, and display the test curve and the test result in real time by the microcomputer screen, and print the test report and the test curve by the printer。The system has a return function, after the test, the loading cylinder piston can automatically or manually return to the initial position。

Test software built-in standard network interface, test data can be transmitted to the network through this standard interface, the software manual and help documents have detailed description of this interface and the use of configuration methods, network software through this interface and test software data exchange and transmission。We assist users in networking, but do not customize the network interface for users alone, nor do we assume the responsibility for consultation and coordination with the relevant network companies。If it involves sending software personnel to the user site service, corresponding fees will be charged。

Relevant standards:

GB/T 2611 "General Technical Requirements for Testing Machine"

GB/T 16826 "Electro-hydraulic Servo universal Testing Machine"

JJG 1063 "Electro-hydraulic Servo Universal Testing Machine"

GB/T 228.1 "Metal materials tensile test - Part 1: Test method at room temperature"

Technical indicators:

Specification and model | SHT4605 |

Maximum load (kN) | 600 |

Testing machine class | 1(0.5)级 |

Relative error of test force indication value | ±1(±0.5)%以内 |

Test force measurement range | 1%~100%FS |

Test force resolution | 1/500000FS (full range ungraded) |

Relative error of deformation indication | ±1(±0.5)%以内 |

Displacement resolution (mm) | 0.013/0.007 |

Relative error of displacement indication | ±1(±0.5)%以内 |

Test force loading rate range | 0.02%-2%FS/s |

Master cylinder piston stroke (mm) | 250 |

Main cylinder piston rising speed (mm/min) | 140 |

Number of columns | 6 |

Effective distance between columns (mm) | 430 |

Maximum stretching space (mm) | 710 |

Maximum compression space (mm) | 630 |

Holding range of round specimen holder (mm) | Φ10~Φ40 |

Plate specimen holding thickness (mm) | 2~30 |

Pressure plate size (mm) | Φ150 |

Main machine dimensions (L × W × H, mm) | 940×650×2400 (excluding piston lift stroke) |

Oil source dimensions (L × W × H, mm) | 1150×600×900 |

Host power supply | 3 to 3W+N+PE, 50Hz |

Total power (kW) | 4kW (380V) +1.5kW (220V) |

Machine weight (kg) | 约2500 |